Representative Work

Water Supply & Wells

High-capacity municipal wells throughout California valley, coastal, and hard rock environments

Pump stations up to 5,000 gpm and 800 hp

Aquifer storage & recovery (ASR) facility design

Surface water intake using Vertical Turbine and High Lift pumps

Treatment Facilities

Surface water treatment plants using Conventional and Alternative Treatment Technologies

Wellhead pressure filters operation and design (greensand, anthracite, I/X, GAC, adsorption)

Groundwater treatment system selection and design (arsenic, iron & manganese, methane, hex chrome)

Pipelines & Distribution

Transmission mains and distribution system design 6-inch through 24-inch diameter

Horizontal directional drilling projects beneath lakes

Meter installation programs and water loss reduction

Reservoirs and booster pump stations

20+ years across California, including work performed at previous firms

Planning & Resilience

Water Master Plans, Urban Water Management Plans (UWMP), EPA Risk and Resilience Assessments

Hydraulic modeling using Infowater, OpenFlows (WaterCAD/WaterGEMS)

Developer project water supply/demand and capacity analysis

Asset management plans, GIS database development

Wastewater & Septic Systems

Large-scale onsite wastewater treatment systems

Pressure and gravity conveyance and dispersal fields

Groundwater impact and nitrate loading studies

Regulatory compliance with SWRCB & local regulators

Lift Stations for wastewater and stormwater

Sustainable & Alternative Building Design

Alternative building materials (Hempcrete, pre-fabricated assembly design)

Structural and architectural design and drafting

HVAC alternatives, analysis and selection

Title 24 energy analysis

Approach

Approach

At Shobe Engineering, we see every project as a partnership. Our work is rooted in collaboration — listening carefully to our clients and communities to understand their goals, challenges, and vision for the future. By combining decades of municipal water and wastewater experience with innovative planning and sustainable design, we deliver infrastructure solutions that are both resilient and practical. Our focus is always on creating systems that serve reliably today and stand strong for generations to come.

Featured Projects

Completed and in-progress by Shobe Engineering

Town of Discovery Bay Community Services District

Union Public Utility District

Laurel Tree Charter School

Hempcrete Building Factory Development

Town of Discovery Bay Community Services District

Community Overview

Set in Delta waterways of eastern Contra Costa County, Discovery Bay is a close-knit, waterfront community home to nearly 16,000 residents. Groundwater supplied from wells is treated at two centralized plants with 10 million gallons per day iron and manganese removal, storage and booster facilities.

Engineering Services

2025 Urban Water Management Plan (UWMP) - guiding long-term water planning and sustainable strategies for a growing community.

EPA Risk and Resilience Assessment (RRA) - enhancing the security and robustness of the water system against evoling challenges.

General Engineering Support - ongoing technical assistance with water system planning and compliance.

Union Public Utility District

Community Overview

Serving the Sierra foothill towns of Murphys and Vallecito, Union Public Utility District carries forward a legacy of water service that dates back to California’s mining era. With deep historical roots and water rights that shaped the Utica Water and Power Authority, UPUD continues to provide both domestic and raw water to its community with two separate systems.

Engineering Services

Shobe Engineering is preparing UPUD’s comprehensive Water Master Plan, developing detailed hydraulic models for both the domestic drinking water and raw water systems, and guiding long-range planning efforts. This work will help the district maintain reliable service, strengthen resiliency, and ensure that its unique water systems continue to serve the community for generations.

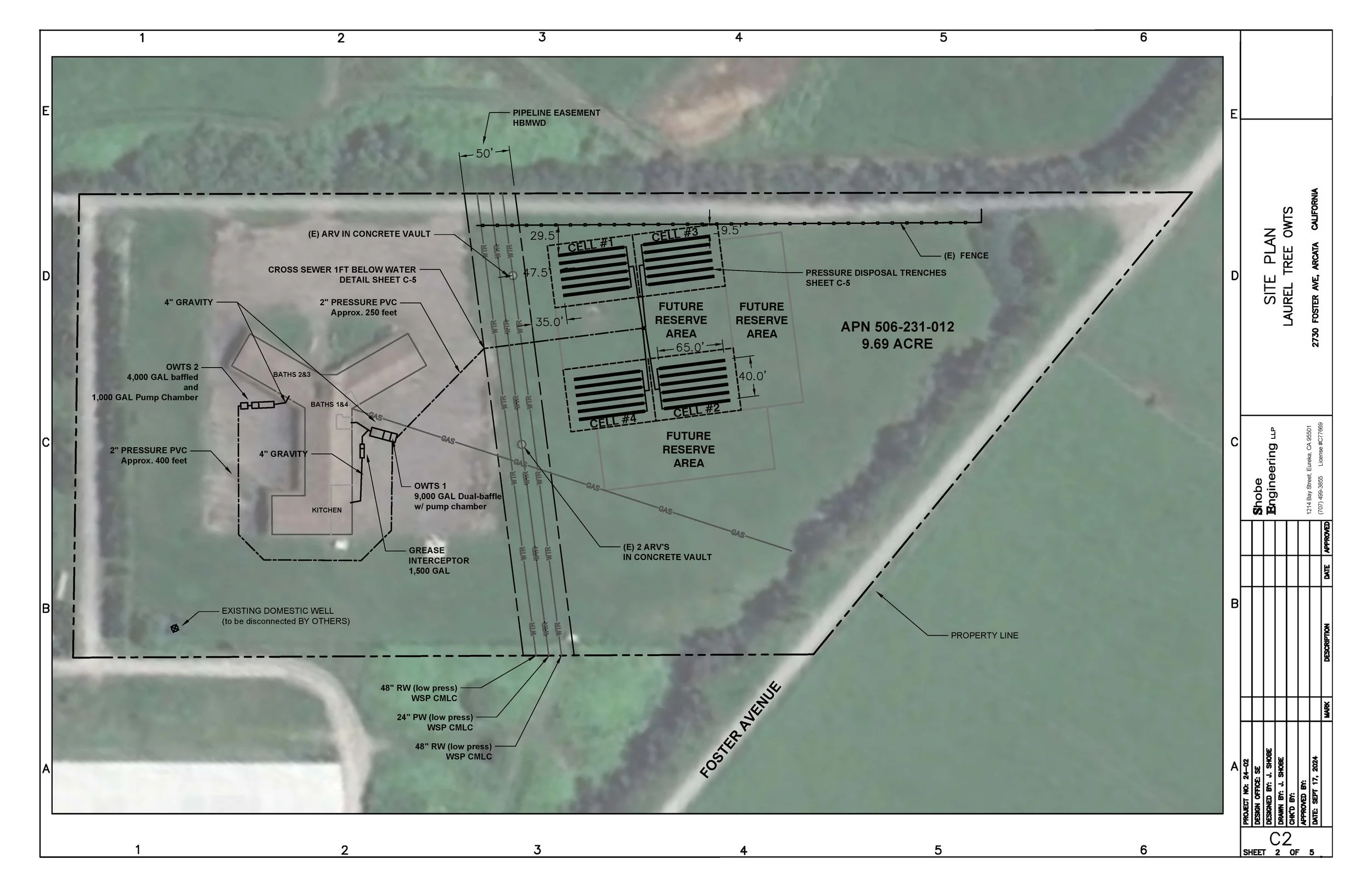

Laurel Tree Charter School

Engineering Services

Located in Arcata, the school recently acquired a new campus to serve more than 300 students and faculty. To secure occupancy permits the school required a new onsite wastewater treatment system, complying with RWQCB Local Area Management Plan, and a new water supply system for the fire suppression system. Working closely with county regulators, building officials, and water and fire authorities, Shobe Engineering secured permits and facilitated construction under an accelerated timeframe, enabling the school to obtain its occupancy permit and begin operations at the new campus.

Design of two large-scale OWTS for school facility.

Groundwater Impact Study and Nitrate Loading Study.

Compliance with Humboldt County LAMP and SWRCB requirements.

Rapid permitting and contractor coordination to meet school occupancy needs.

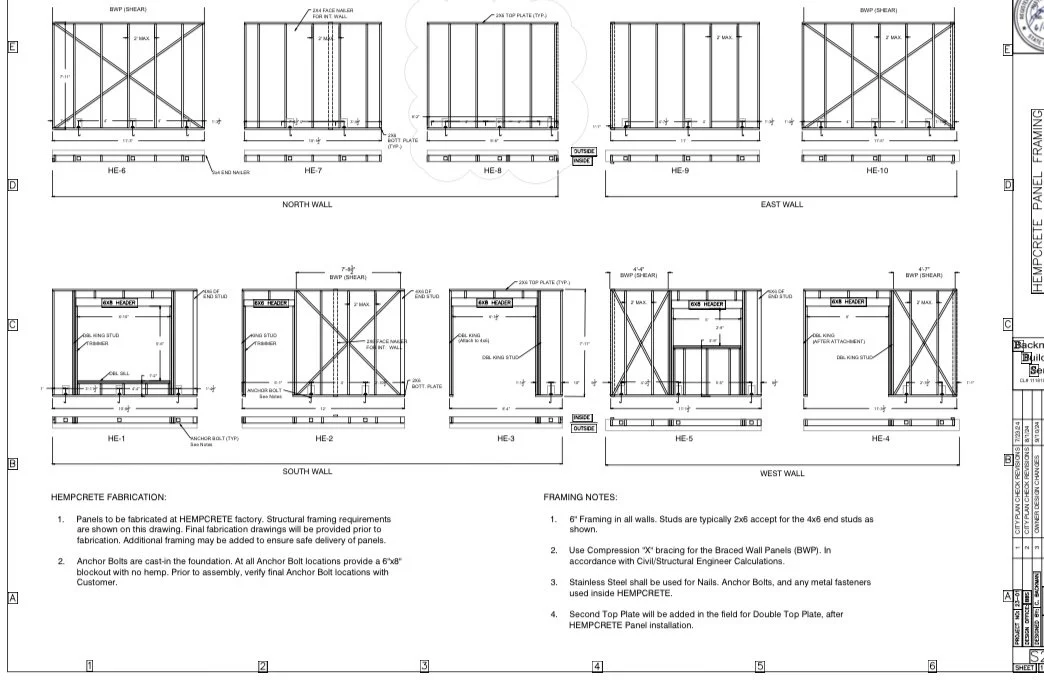

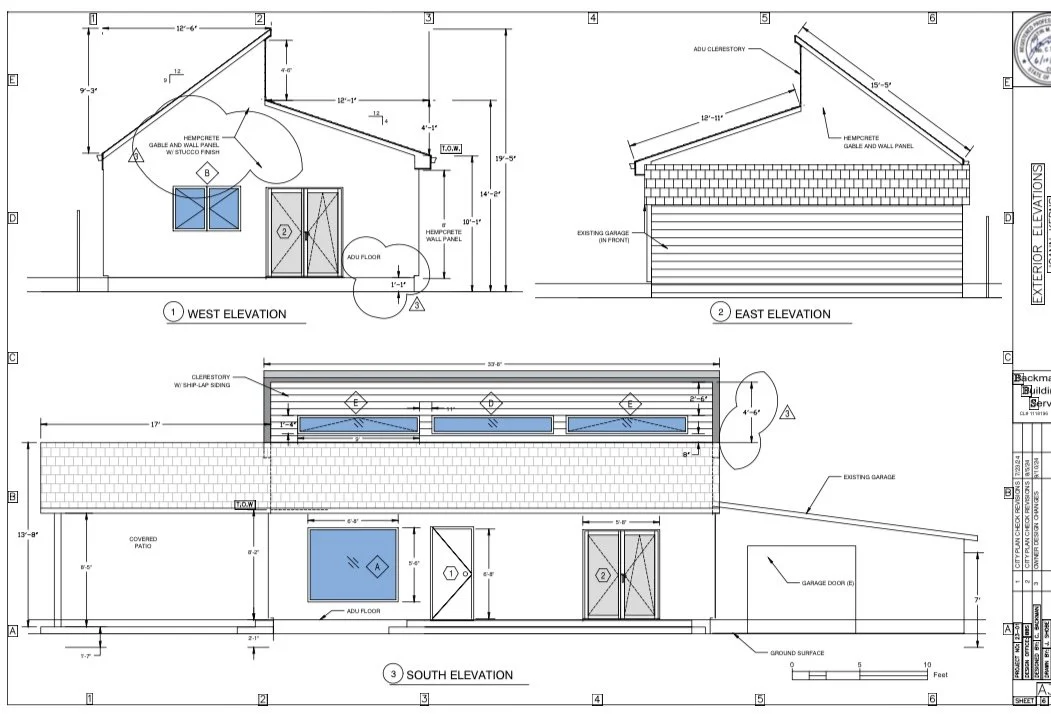

Hempcrete Factory Assembled Home

Shobe Engineering and Backman Building Services LLC designed and built the first factory-assembled hempcrete home in Humboldt County. We developed prefabricated wall panels that met California seismic and wind codes without conventional sheathing, showcasing sustainable, natural materials and rapid on-site assembly. This project demonstrates the potential for regional hempcrete manufacturing and innovative, low-carbon housing solutions.

Working with the Indigenous Habitat Institute (IHI) and their European supply partners, we developed an innovative prefabricated wall panel system using hemp and lime sourced overseas. Shobe Engineering and Backman Building Services solved the structural challenges, designing panels that could be poured horizontally in a factory setting, cured, and then transported to the job site for rapid assembly.

Over several months, our team transformed an old warehouse into a startup factory space where wall panels were framed, poured, and lifted into place. Once cured, panels were trucked to the build site and set in a single day, followed by roof construction using a double-roof rain screen assembly. The project relied on sustainable materials throughout, including hemp insulation from Hempitecture and lime plaster finishes reminiscent of European design.